Wednesday, February 24, 2016

Thursday, February 18, 2016

Blog 17 – Interview 3 Reflection

Wednesday, February 10, 2016

Blog 16 – Independent Component 2 Approval

|

The empennage, commonly known as the tail assembly, is the rear section of the aircraft body. It's main purpose is to provide stability to the aircraft.

|

Thursday, February 4, 2016

Independent Component 1

|

| ~All of the materials we will use for empirical testing/experimentation. These are all of the printed/manufactured coupons(test samples). |

"How can aircraft manufacturers utilize today's technology in order to be cost efficient?"

LITERAL

- (a) Write: “I, Justin Ilagan, affirm that I completed my independent component which represents 34 hours of work.”

- (b) Cite your source regarding who or what article or book helped you complete the independent component.

- “Composite Materials Handbook Volume 3. Polymer Matrix Composites Materials Usage, Design, and Analysis.” United States Department of Defense, 17 June 2002. PDF File.

- J.F.M. Wiggenraad, P. Arendsen and J.M. da Silva Pereira. "Design optimization of stiffened composite panels with buckling and damage tolerance constraints." National Aerospace Laboratory NLR, 1998. PDF File.

- Federal Aviation Administration, U.S. Department of Transportation. "Aviation Maintenance Technician Handbook - Airframe, Volume 2 Chapter 1: Aircraft Structures." DOT, FAA, 2012. PDF File. <http://www.faa.gov/regulations_policies/handbooks_manuals/aircraft/amt_airframe_handbook/media/ama_ch01.pdf><http://www.faa.gov/regulations_policies/handbooks_manuals/aircraft/amt_airframe_handbook/>.

- Federal Aviation Administration, U.S. Department of Transportation. "Aviation Maintenance Technician Handbook - Airframe, Volume 2 Chapter 5: Welding." DOT, FAA, 2012. PDF File. <http://www.faa.gov/regulations_policies/handbooks_manuals/aircraft/amt_airframe_handbook/media/ama_ch01.pdf><http://www.faa.gov/regulations_policies/handbooks_manuals/aircraft/amt_airframe_handbook/>.

- Gjøvik, Raufoss. "Additive Manufacturing Technology Industrial demonstrators and Living labs." SFI Norman, 2008. PDF File.

- Palmer, Dave. "Strength & Stiffness: What's the Difference?" DesignNews. DesignNews, 17 Sept. 2014. Web. 03 Dec 2015.

- Ruplu Bhattacharya and Mohan Wamsi. "Primer: 3D printing, Early days for a disruptive space." Bank of America Meryll Lynch, 2013. PDF File. <http://www.designnews.com/author.asp?section_id=1365&doc_id=274793&dfpPParams=ind_183,aid_274793&dfpLayout=blog>.

- Woodford, Chris. “Composites and Laminates.” Explainthatstuff. Explainthatstuff, 13 July 2015. Web. 31 Jan 2016. <http://www.explainthatstuff.com/composites.html>.

- (c) Update your hours in your Senior Project Hours link. Make sure it is clearly labeled with hours for individual sessions as well as total hours.

- Done

- (d) Explain what you completed.

- I have done extensive research on aircraft wing spar structures and other types of supporting structures. I went through hundreds of designs in which all had different structure configurations. I drafted the best baseline designs possible for experimentation and have revised them. With the help of my mentor, I was able to have these baseline designs manufactured and ready to be tested in a lab.

INTERPRETIVE

- Defend your work and explain its significance to your project and how it demonstrates 30 hours of work. Provide evidence (photos, transcript, art work, videos, etc) of the 30 hours of work.

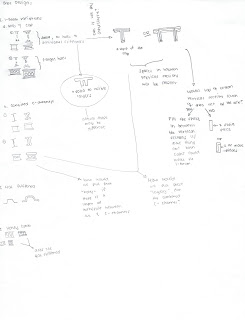

- More than half of the time spent on my Independent Component 1 can only be proven by looking at the sources/references used for my research. This is because of the amount of reading I had to do. Most of the sources I used for IC1 were about 40 pages. Moreover, I have spent countless hours note-taking and drafting my designs. I have also spent about 8-10 hours doing discussions with my mentor, Eric Fodran. Below, you can find evidence of some of the notes I have taken, as well as the drafts and the manufactured coupons(test samples). The sources I used for my IC1 can be found above--question (b).

- Online Notes/Outlines

- https://docs.google.com/document/d/1C77BCYo0GdDtuForBemo4F1Bdfyq2tJ7LjggxD8YOy4/edit?usp=sharing

- https://docs.google.com/document/d/1xeCVZPdlj3rW67eabr_wtz01P5LKoMs-LJKgGhOhtJU/edit?usp=sharing

- Notes

- Draft 1

- Draft 2

- Printed/Manufactured objects

|

| ~Gjøvik, Raufoss. "Additive Manufacturing Technology Industrial demonstrators and Living labs." SFI Norman, 2008. PDF File. |

|

| ~Gjøvik, Raufoss. "Additive Manufacturing Technology Industrial demonstrators and Living labs." SFI Norman, 2008. PDF File. |

|

| ~Ruplu Bhattacharya and Mohan Wamsi. "Primer: 3D printing, Early days for a disruptive space." Bank of America Meryll Lynch, 2013. PDF File. |

|

| ~Ruplu Bhattacharya and Mohan Wamsi. "Primer: 3D printing, Early days for a disruptive space." Bank of America Meryll Lynch, 2013. PDF File. |

|

| ~Federal Aviation Administration, U.S. Department of Transportation. "Aviation Maintenance Technician Handbook - Airframe, Volume 2 Chapter 1: Aircraft Structures." DOT, FAA, 2012. PDF File. |

|

| ~Federal Aviation Administration, U.S. Department of Transportation. "Aviation Maintenance Technician Handbook - Airframe, Volume 2 Chapter 5: Welding." DOT, FAA, 2012. PDF File. |

|

| ~Draft 1 |

|

| ~Draft 1 revision |

|

| ~All of the materials we will use for empirical testing/experimentation. These are all of the printed/manufactured coupons. |

|

| ~Topside view of woven laminate coupons |

|

| ~Angled view of woven laminate coupons |

|

| ~Topside view of unidirectional laminate coupons |

|

| ~Angled view of unidirectional laminate coupons |

|

| ~Topside view of T-stiffened |

|

| ~Angled view of T-stiffened |

|

| ~Cross-section view of T-stiffened |

|

| ~Topside view of reinforced honeycomb structure |

|

| ~Angled view of reinforced honeycomb structure |

|

| ~Cross-section view of reinforced honeycomb structure |

APPLIED

- How did the component help you understand the foundation of your topic better? Please include specific examples to illustrate this.

- With the research I have done for my Independent Component 1(I.C.1), I have gained a better understanding on how certain geometrical factors can significantly decrease the overall weight of an aircraft. Before starting on I.C.1, I wasn’t aware of how much composites can improve the weight/performance ratio of certain components. This project really opened up many possible answers that I can use for my essential question. It gave me a new perspective and something different to look for in my research. An example would be the vast topic of additive manufacturing. When comparing additive shaping techniques to subtractive shaping, it is evident that any aircraft manufacturer can increase profitability of their aircraft in the long run. Information on additive/subtractive manufacturing can be found on "Additive Manufacturing Technology Industrial demonstrators and Living labs" by Raufoss Gjøvik, and "Primer: 3D printing, Early days for a disruptive space" by Ruplu Bhattacharya and Mohan Wamsi. Another way my IC1 helped me understand the foundation of my topic better would be by introducing the importance of strength/stiffness to weight ratio of aircraft components. Like I have said before, before doing my Independent Component 1, I was looking at completely different answers(i.e. aerodynamics, engines, etc.); however, my IC1 has opened up a wide array of possible answers to my essential question. Information on strength and stiffness can be found on "Strength & Stiffness: What's the Difference?" by Dave Palmer. While there are many other ways that my Independent Component 1 has helped me understand the foundation of my topic(Aerospace Engineering), I find that the 2 reasons states above are most significant.

Wednesday, February 3, 2016

Blog 15 – Lesson 2 Reflection

- What are you most proud of in your Lesson 2 Presentation and why?

- I was most proud of my hook activity (ice sheet vs. ice sheet composite). It was a nice seeing everyone’s reaction to my activity. Moreover, my activity was well thought of and required a lot of preparation/planning. I am proud that it was both fun/engaging and relevant to my EQ answer.

- -

- What assessment would you give yourself on your Lesson 2 Presentation (self-assessment)?

- I would give myself a P+/AE

- Explain why you deserve that grade using evidence from the Lesson 2 component contract.

- I believe I deserve this grade because I was able to meet all of the requirements and did not have any problems with any of them. I wouldn’t give myself a full AE because I was very close to going over time and had to cut the activity debrief short.

- What worked for you in your Lesson 2?

- My activity and my hook worked well for my Lesson 2.

- What didn't work? If you had a time machine, what would you have done differently to improve your Lesson 2?

- Timing was definitely very awkward for me. If I could have done differently to improve my Lesson 2 I would have tried to remove some unnecessary points in order to help my timing.

- What do you think your answer #2 is going to be?

- For my answer 2, I think I am going to try to expand upon composite materials and structures. I want to go to a completely different direction with my 3rd answer, but for now, I would like to expand upon composites.

Subscribe to:

Posts (Atom)